Introduction

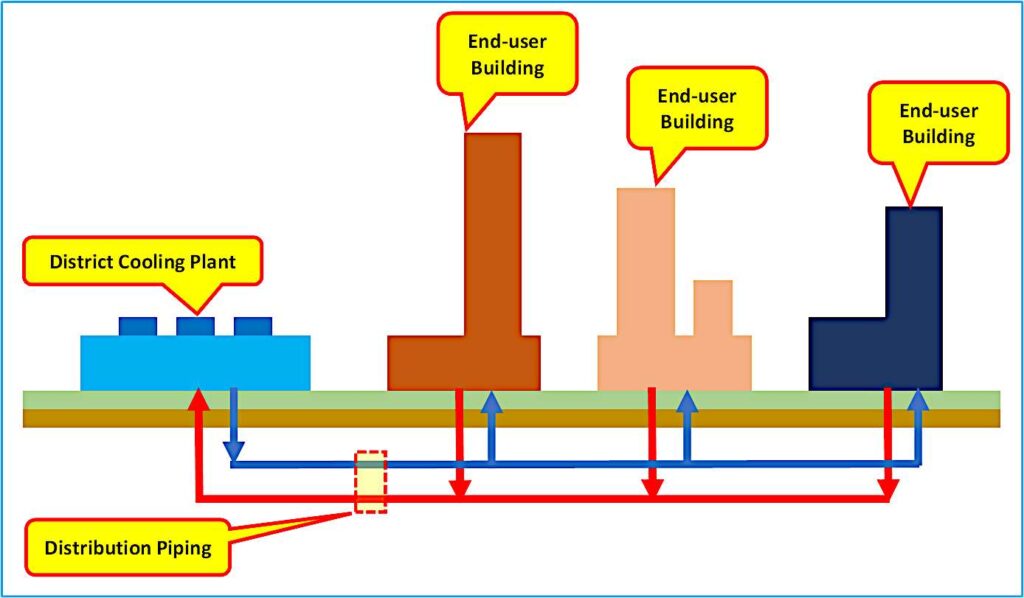

In every district cooling network, the pumping system serves as the circulatory system, ensuring chilled water—the “life-blood” of the system—reaches every building, even those at the hydraulic periphery. The choice of pumping scheme directly influences energy efficiency, operational reliability, and long-term sustainability. While often overlooked, these systems are pivotal in minimizing energy consumption, reducing carbon footprints, and maintaining cost-effective operations.

This article explores the foundational and advanced pumping strategies that define modern District Cooling Systems (DCS), emphasizing their role in achieving sustainable urban infrastructure. From constant-speed setups to intelligent distributed pumping, we’ll dissect how engineering ingenuity shapes efficient cooling networks.

Why Pumping Matters in District Cooling

Energy Consumption and Cost Impact

Pumping chilled water typically accounts for significant percentage of a DCS’s total energy use. However, inefficiencies such as “low delta T (ΔT) syndrome”—where the temperature difference between supply and return water reduces due to poor coil performance or control valve misoperation, can increase energy demand substantially. For instance, doubling flow rates to compensate for low ΔT can increase pumping power eightfold, owing to the cubic relationship between flow and power in centrifugal pumps. This not only escalates energy costs but also strains the entire cooling infrastructure.

System Efficiency and Heat Gain

Excessive pumping introduces parasitic heat gains into the chilled water loop. This “waste heat” forces chillers to work harder, compounding energy use. In large distribution networks, this parasitic heat gain can be substantial. Optimal pumping minimizes these losses, ensuring that the cooling capacity is used efficiently and that the system operates as close to its design intent as possible.

Reliability and Performance

Consistent pressure and flow are essential for uninterrupted cooling. Poorly designed pumping systems risk cavitation, pressure surges, or inadequate flow to remote buildings, undermining occupant comfort and equipment longevity.

Core Pumping Schemes in District Cooling

The choice of pumping scheme forms the fundamental operational strategy for a DCS, with each approach offering distinct advantages and disadvantages.

Constant Speed (CS) Primary Pumping

In constant speed primary pumping systems, chillers operate in parallel with fixed-speed pumps maintaining a steady flow through evaporators. While simple and low-maintenance, this approach is not energy efficient under part-load conditions due to the following factors:

- Over-pumping that occurs when demand drops. Due to the fixed speed pumping, the excess flow is bypassed from the chilled water supply line to the return line. This results in wasted pumping energy. At the same time, the excess flow that is bypassed to the return line reduces the ΔT that is crucial to maintaining chiller efficiency.

- Reduced ΔT results in additional energy penalties, as lower temperature lift forces chillers to operate inefficiently.

Constant speed primary pumping is best suited to small, stable-load systems but struggles in dynamic environments.

Variable Speed (VS) Primary Pumping

Variable speed primary pumping is a growing trend due to its modest energy and first-cost savings advantages and smaller footprint. In this scheme, pumps adjust their speed to maintain a minimum differential pressure at hydraulically remote points in the system, adjusting flow based on actual cooling demand, thus resulting in efficient pump operation.

This approach is particularly beneficial in larger DCS plants, as it ensures that chillers receive the highest possible entering return water temperatures, enhancing overall efficiency. By reducing over-pumping, VS primary pumping also helps mitigate the low ΔT syndrome, making it a preferred choice for modern systems. VS systems thrive in medium-to-large DCS but require precise control algorithms to avoid instability.

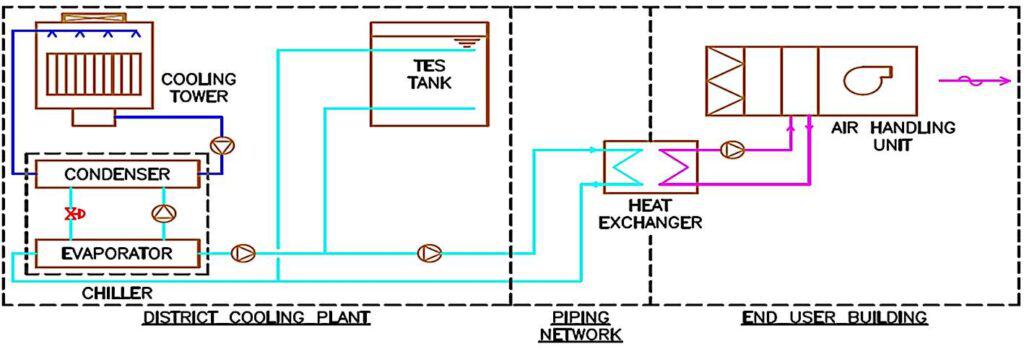

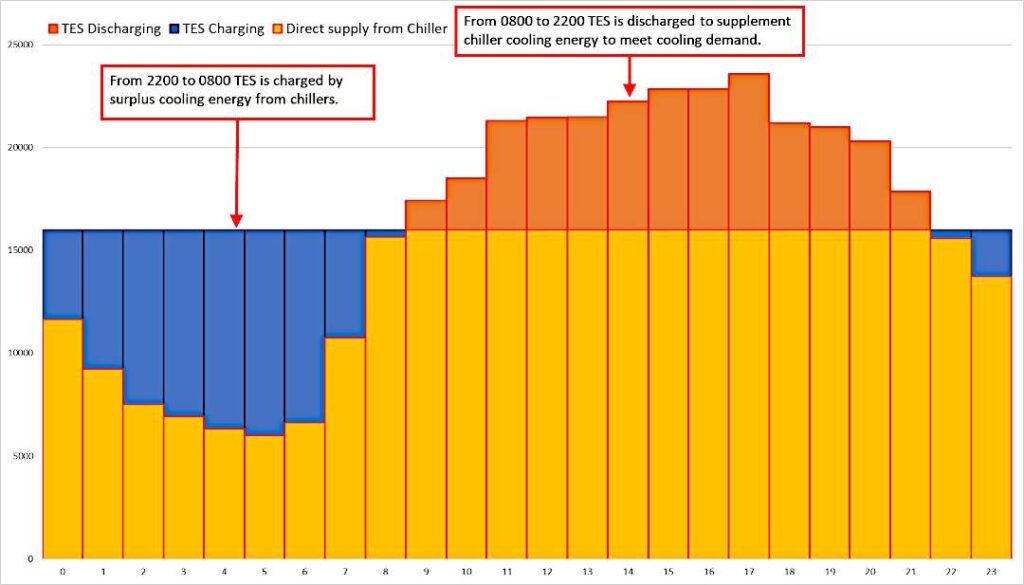

Primary-Secondary (Decoupled) Pumping

This common configuration hydraulically separates the chiller (primary) loop from the building distribution (secondary) loop using a bypass pipe or “decoupler.” It allows constant flow through the chillers while enabling variable flow to the loads, providing flexibility and stable chiller operation. Although this scheme may incur higher installation costs due to additional pumps and piping, it offers reliability and ease of control, making it a popular choice for many DCS applications.

With this pumping scheme, it is relatively easy to integrate chilled water storage tanks into the system by connecting the tanks to the decoupler line. See schematic for more details.

Advanced and Specialized Pumping Strategies

Primary-Distributed Secondary Pumping

In this scheme, chilled water is primarily circulated by central plant pumps, but individual customer buildings house their own secondary pumps that manage flow through their internal HVAC systems. This reduces pressure within the central plant and avoids secondary pump surge, but it introduces installation and energy costs at each Energy Transfer Station (ETS). This strategy is attractive when development loads are well-known and the network length is not extensive. However, it can limit flexibility if future load requirements are uncertain, as the distributed pumps may not easily adapt to changes in demand.

Series Chiller Arrangements

Chillers can be arranged in series-counterflow, meaning both evaporators and condensers are in series. This arrangement increases overall chiller-module efficiency because the compressor lift is split between two units, particularly when dealing with large CHW ΔTs (greater than 16°F or 8.9°C). Such designs can greatly reduce pumping costs due to lower required flow rates on both the chilled water and condenser water sides. By minimizing flow, series arrangements also reduce pipe sizes and pumping energy, making them an efficient choice for systems with high cooling demands.

Booster Pumps for System Expansion

For very large distribution systems or interconnections of multiple subsystems, booster pumps can be used at strategic points. These pumps allow chilled water transmission over longer distances as an alternative to increasing distribution pipe size or for enhancing capacity in existing constrained systems. However, booster stations involve significant capital investment and increased pumping energy costs, so a thorough life-cycle cost analysis is essential to justify their use. When properly implemented, booster pumps can extend the reach and capacity of a DCS without the need for extensive infrastructure upgrades.

Optimizing Pumping Performance Through Design and Control

Maximizing Delta T (ΔT)

Achieving a high ΔT—the temperature difference between supply and return water—is critical for reducing flow rates, which in turn allows for smaller pipes and lower pumping energy. Best practices to maximize ΔT include:

- Using variable flow on both the district and customer-sides.

- Specifying cooling coils with a minimum of six rows to maximize heat transfer.

- Eliminating three-way valves in favor of high-quality two-way pressure independent control valves (PICVs) at terminal units. These measures ensure that the system operates efficiently, even under varying load conditions.

Intelligent Control and Automation

Sophisticated District Cooling Instrumentation and Control Systems (DCICS) are essential for optimizing pump dispatch, especially for variable-speed pumps. Control logic should incorporate time delays and hysteresis to minimize pump cycling and pressure fluctuations. Integration with Building Management Systems (BMS) allows for dynamic adjustments, such as linking pump speed to return temperature, ensuring efficient operation across the entire network. Advanced controls not only enhance energy efficiency but also improve system reliability by preventing issues like pump hunting and flow instability.

Overall System Design

Pumping arrangements must be designed with the entire DCS in mind, including the central plant, distribution network, and consumer interconnections. Early planning and detailed hydraulic analyses are crucial for optimal pipe sizing, balancing capital costs with long-term pumping energy and future expansion capabilities. A well-designed system ensures that pumping strategies align with the overall goals of the DCS, providing a scalable and efficient cooling solution for years to come.

Conclusion

The evolution of pumping strategies—from rudimentary constant-speed setups to AI-driven distributed systems—reflects the industry’s push for sustainability and resilience. By embracing variable-speed drives, high ΔT design, and leveraging intelligent controls, engineers can significantly enhance energy efficiency, reduce operational costs, and contribute to a more sustainable urban environment.

References:

- Ashrae Owner’s Guide for Buildings Served by District Cooling

- Ashrae District Cooling Guide

- IDEA District Cooling Best Practice Guide

- Trane Applications Engineering Manual – Chiller System Design and Control