Contents

Summary

District cooling system has two major competitive advantages over in-building cooling plants, which makes it a cost-effective and energy-efficient solution for urban comfort cooling. The two advantages are:

- Efficient Asset and Resource Utilization

- Efficient Energy Utilization

This article discusses in detail the competitive advantages of a district cooling system compared to conventional in-building cooling plants.

Introduction

In conventional comfort cooling in an urban environment, each building is equipped with its own cooling system. The cooling capacity depends on the size and the usage of the building. The building cooling demand determines the type of cooling technology. Smaller offices and residential buildings are typically provided with air-cooled technology, which has higher unit energy consumption. Larger commercial or office buildings will invariably be installed with water-cooled electrical chillers.

In a modern city with an equatorial climate, like Singapore, approximately 70% of electricity consumption in commercial buildings is attributed to comfort cooling and two-thirds of that consumption is used to power the in-building chiller plants.[1] This energy statistic underscores the importance of optimizing the energy usage of air conditioning in the urban environment. District Cooling technology holds the promise of significant improvement in the energy efficiency of comfort cooling.

A district cooling system does away with the in-building cooling plants by providing a centralized source of energy as a utility service. The District Cooling model comprises a Central Chiller Plant generating cooling energy to be supplied to each individual End-user building via a network of distribution pipes.

District cooling systems have certain competitive advantages compared to conventional in-building cooling plants. These advantages translate into real-world benefits, which make district cooling technology a cost-effective and energy-efficient cooling solution for comfort cooling in the modern city.

Efficient Asset and Resource Utilization

Diversity in Building Peak Cooling Loads

In a district cooling system, each individual End-user building experiences its peak cooling load at various times of the day. By aggregating the cooling load from these same buildings, the district cooling system will “see” load diversity between these End-users and will experience a total cooling demand which is significantly less than the total sum of the individual building peak cooling loads.

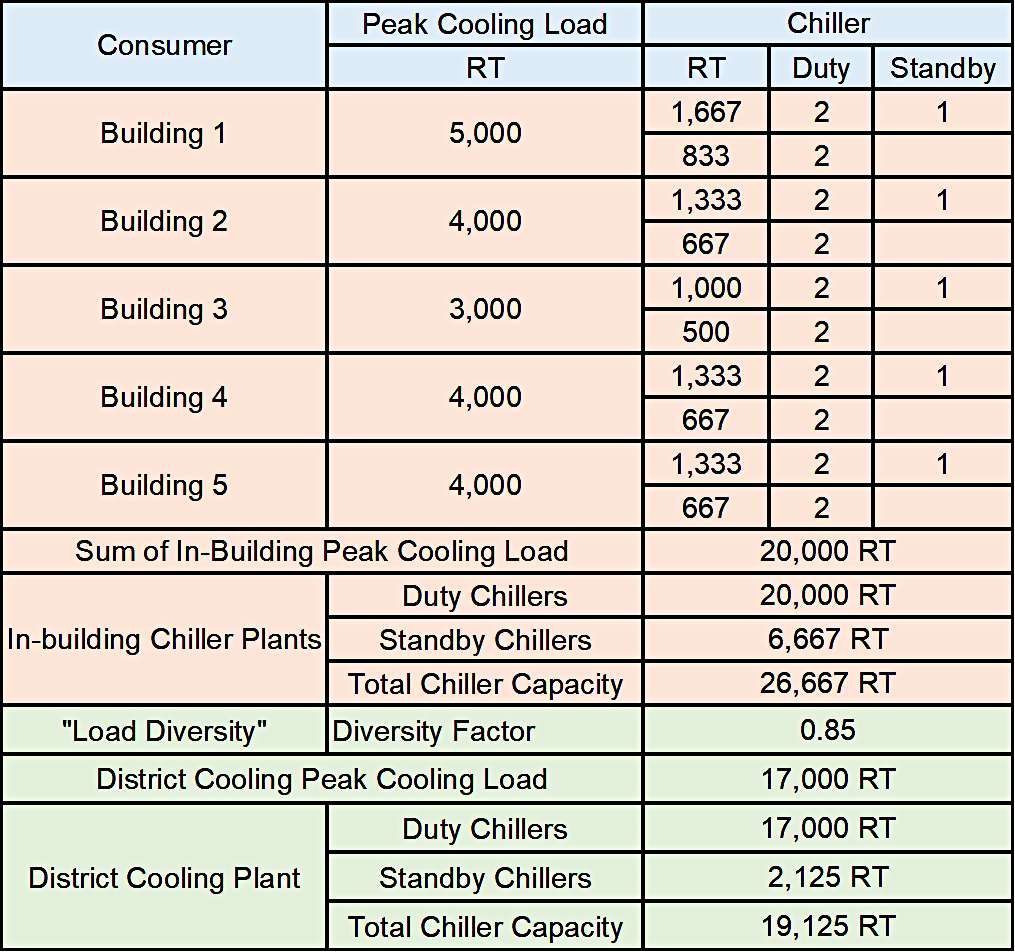

See the table below for an illustration of the concept.

Referring to data in the above table, assume that in a district cooling system, the total peak cooling demand of the consumer buildings is equal to 20,000RT. With a load diversity of 85%, the district cooling plant cooling capacity works out to be: 20,000RT x 85% = 17,000RT. Considering the requirement for chiller redundancy in each building, the total installed chiller capacity for conventional in-building chiller plant system = 26,667 RT. On the other hand, the installed chiller capacity for the District Cooling Plant (considering the provision for redundant chiller) is 19,125RT, which is approximately 28.3% lower compared to in-building cooling systems.

Through “load diversity” a district cooling system has an installed capacity which is significantly smaller than the sum of the peak cooling demands of the individual buildings. The savings in initial capital investment are further magnified when the requirement for equipment redundancy at the individual consumer building is considered.

In a district cooling system, the following real-world capital savings can be realized:

- Savings in capital investment due to lower aggregate cooling capacity and better economy of scale.

- Omission of capital investment in dedicated in-building cooling plants will result in lower investment risk and higher Return on Investment for the Building Owner.

In a real-world application, because of the small margin for error in the estimation of in-building cooling capacity, it is not uncommon for the design engineer to “err on the side of caution” and apply a significant amount of buffer to the design capacity of the cooling system. The result is that in-building installed cooling capacity has been known to exceed actual peak cooling demand by a factor of 50%-300%. [1]

Thermal Energy Storage reduces installed chiller capacity

In conventional in-building cooling plants (without thermal energy storage), the operating chiller capacity must be sized, at the minimum, to meet the peak load of the building, which occurs for an hour or so over a 24-hour period.

The large capacity of a district cooling plant favors the adoption of thermal energy storage technology. Thermal energy storage effectively decouples the production of cooling energy from the End-user demand. The required chiller operating capacity of a district cooling plant with thermal energy storage is sized based on the average of the total 24-hour cooling load. Compare this to a non-thermal energy storage installation with a similar load profile, where it would be necessary to size the chiller operating capacity to be at least equal to the peak cooling load over the 24-hour period.

Referring to the 24-hour load profile as shown in the above bar chart. A conventional non-thermal energy storage system will have its chiller operating capacity sized to match the peak cooling load of 23,600RT. On the other hand, a District Cooling Plant with Thermal Energy Storage can have its chiller operating capacity sized based on the average cooling load, over a 24-hour period of 16,000RT. This translates into a reduction in chiller operating capacity of 32.2%.

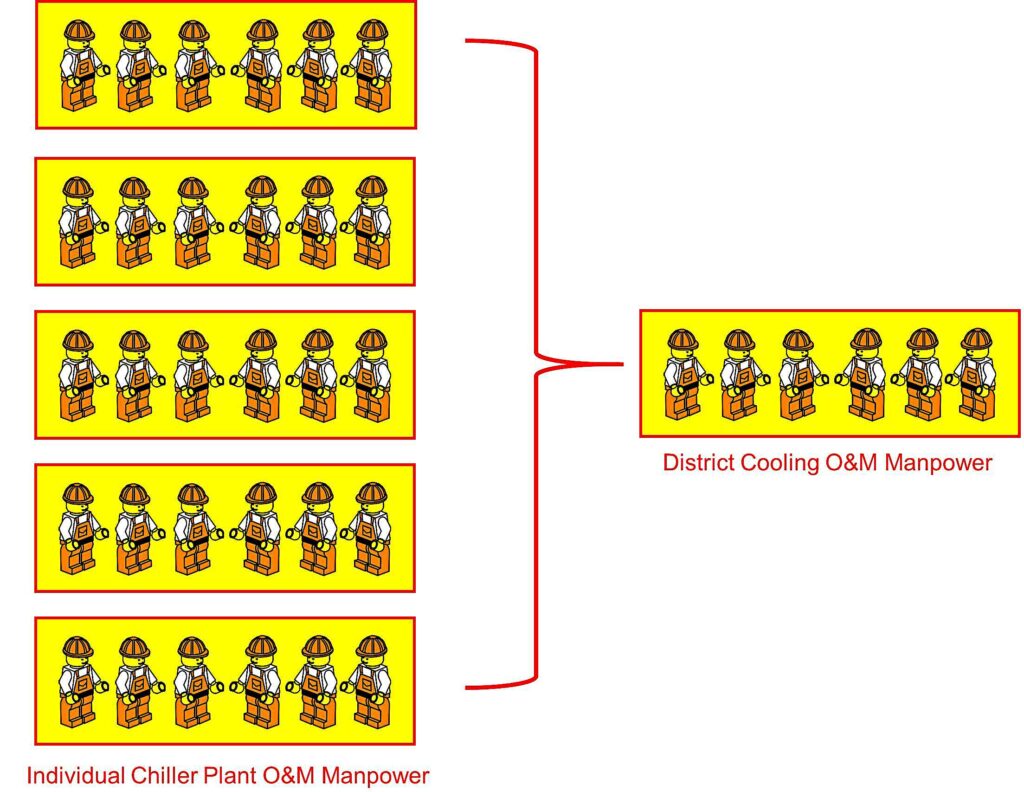

District cooling optimizes on manpower resources for operation and maintenance

District cooling reduces the manpower required to operate and maintain the in-building cooling plant at each End-user building. A single team of highly skilled O&M Specialists can replace multiple teams.

By aggregating the cooling demand from many consumers into a centralized chilled water plant, district cooling can optimize the manpower resources required for the operation and maintenance of the system. District cooling plants often utilize industrial-grade distributed control systems for a high degree of plant automation, resulting in additional efficient utilization of plant manpower resources.

Efficient Energy Utilization

District cooling helps to improve energy efficiency of comfort cooling, both on-site as well as at source.

Economies of scale allow district cooling plants to adopt technology options thermal energy storage, which helps to decouple the generation of cooling energy from the demand. The decoupling allows the optimization of chiller sizing and chiller operation, which enhances energy efficiency.

Advantages of thermal storage technology include the following:

- Site Energy efficiency improvement

- Load leveling or peak shaving operation mode shifts a substantial percentage of chiller operation from peak hours to off-peak hours. Compared to peak hours, chillers operate more efficiently during the off-peak hours because of the lower ambient temperature.

- Thermal energy storage enables chillers to operate continuously at close to full capacity and optimum efficiency, thus further improving the energy utilization of the chillers.

- Low flow, high chilled water delta T design also contribute to improved chilled water pumping efficiency.

- Source Energy efficiency improvement

- From the perspective of the power grid, shifting of power demand from peak hours to off-peak hours are beneficial for a few reasons.

- Reduction in peak power demand will reduce power generation from the less efficient peaking power generators. With the demand shift to off-peak hours, there is more demand for power generation from the base load power generators, which are substantially more energy efficient compared to peak generators.

- In addition, the transmission and distribution losses are also lower during off-peak hours, thus contributing further to the energy efficiency improvement of the power grid.

- ASHRAE’s District Cooling Guide states that:

Independent studies of six large electric utilities in four US states, namely California (Flory 1995; Tabors Caramanis 1995), Florida (Nix 2008), Texas (Reindl et al. 1994), and Wisconsin (Gansler 1999), have documented the dramatic positive impacts of shifting electric energy consumption from on-peak daytime periods to off-peak nighttime periods. Reductions of 20% to 30% and greater were demonstrated in terms of source utility power plant fuel use and emissions of SOX (sulfur oxide), NOX (nitrogen oxide), particulates, and CO2 (carbon dioxide), due to the different performance of the power plant equipment which is on the margin during the different times of day.

ASHRAE DISTRICT COOLING GUIDE, Page 6.11

- Reduction of CO2 emissions

- Improvements in energy efficiency, both on-site and at source, will result in a reduction in CO2 emissions.

Conclusion

To conclude, District Cooling is considered as a cost-effective and energy-efficient solution for comfort cooling for the following reasons:

- Efficient Asset and Resource Utilization

- Diversity in cooling demand enables a district cooling system to have an installed cooling capacity which is lower than the sum of the peak cooling demands of the individual buildings.

- Thermal energy storage further reduces the installed chiller capacity of a District Cooling System.

- District cooling optimizes on manpower resources for operation and maintenance.

- Efficient Energy Utilization

- District cooling helps to improve energy efficiency of comfort cooling, both on-site as well as at source.

- Reduction of CO2 emissions.

Footnotes:

[1]: District Cooling as an Energy and Economically Efficient Urban Utility–Its Implementation at Marina Bay Business District in Singapore