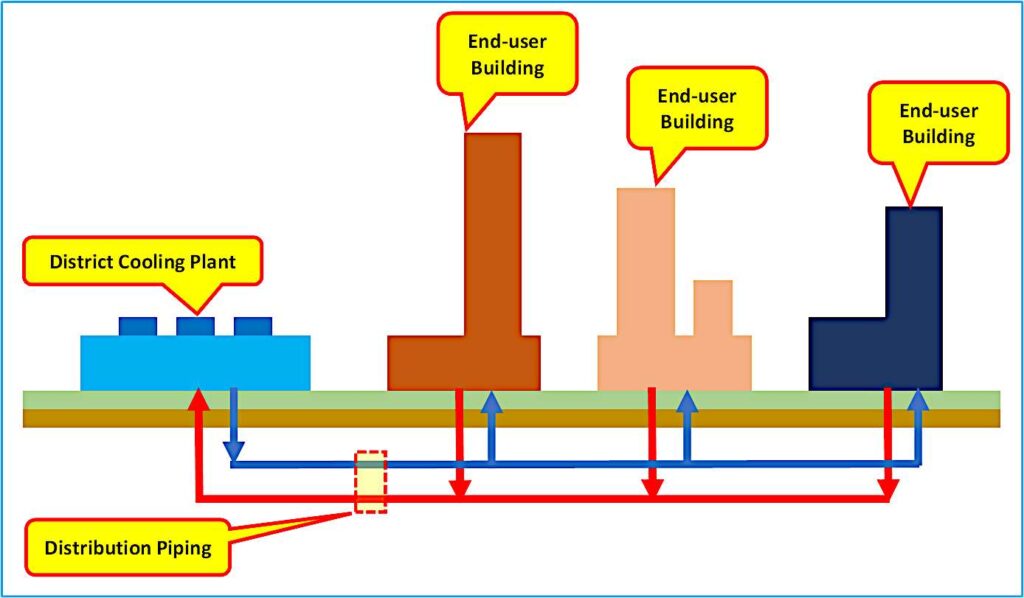

Introduction

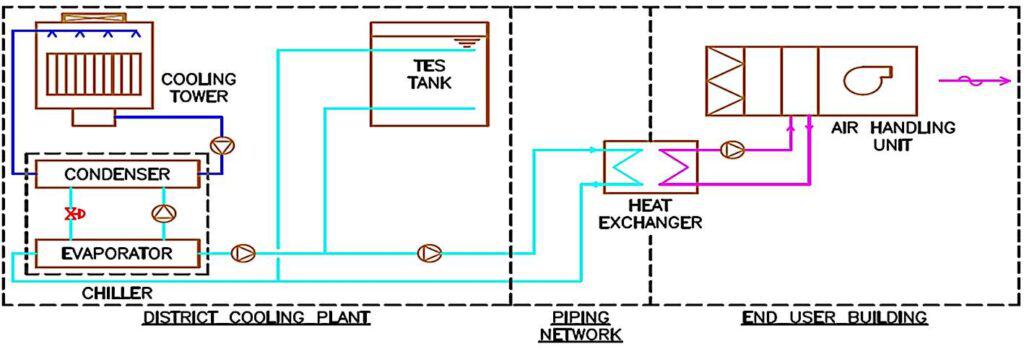

In modern district cooling systems, optimizing the chilled water temperature differential (ΔT) is a fundamental design consideration for improving energy efficiency, reducing operational costs, and minimizing infrastructure demands. A higher ΔT—the difference between supply and return water temperatures—allows for smaller pipe diameters, lower pumping energy, and increased system capacity. However, achieving an optimal ΔT requires careful planning, from chiller selection and coil design to flow control strategies. This article explores the recommended ΔT ranges for district cooling applications, examines real-world case studies, and outlines key design principles to maximize performance. Whether designing a new system or retrofitting an existing one, understanding these factors ensures a cost-effective and sustainable cooling solution.

Recommended Design ΔT Values and Ranges:

The selection of an appropriate chilled water temperature differential (ΔT) is a critical design decision that directly impacts the efficiency, cost, and performance of district cooling systems. While conventional systems often operate at modest ΔT values, modern designs increasingly target higher differentials to optimize energy use and reduce infrastructure requirements. This section outlines industry-recommended ΔT ranges for various applications, from standard district cooling networks to specialized thermal storage systems. By understanding these benchmarks and the factors that influence them, engineers can make informed decisions that balance operational performance with economic and sustainability objectives.

The following recommendations are based on industry standards, case studies, and proven best practices in system design.

- General Range: Typical design ΔT values for district cooling systems generally fall within the range of 12°F to 16°F (6.7°C to 8.9°C) at full load. 1

- Achieving Higher ΔT: With designs that emphasize maximizing ΔT, values as high as 20°F (11°C) or more are possible.2 For new buildings specifically designed for district cooling service, a successful design should be able to achieve a ΔT of 16°F to 22°F (8.9°C to 12.2°C).3

- Chilled Water Storage Systems: For chilled water storage installations, it is conventionally recommended to select a ΔT range between 18°F to 24°F (10°C to 13.3°C).4 Some systems have even installed differentials above 30°F (17°C).5 Increasing the ΔT significantly enhances storage capacity.

Factors Influencing and Enabling High ΔT:

Achieving and maintaining an elevated chilled water temperature differential (ΔT) requires careful consideration of multiple interdependent factors across system design and operation. While higher ΔT values offer significant advantages in energy efficiency and infrastructure savings, their successful implementation depends on optimized chiller performance, proper equipment selection, and intelligent system controls. This section examines the key technical and operational elements that contribute to effective high-ΔT operation, from building-side HVAC configurations to plant-side pumping strategies. Understanding these critical factors enables engineers to design systems that consistently deliver superior ΔT performance while maximizing cost savings and sustainability benefits throughout the district cooling network’s lifecycle.

Selecting an optimal chilled water ΔT requires balancing multiple engineering and economic considerations. The following factors critically influence achievable temperature differentials and system performance in district cooling applications:

- Cost-Effectiveness: Maintaining a high ΔT is the most cost-effective approach, as it allows for smaller pipes in the distribution system and reduces pumping energy consumption.6

- Chiller Performance: The pumping arrangement directly affects chiller performance. Designs that allow for the widest temperature differentials in both chilled-water and condenser-water circuits often result in the best overall plant efficiency gains.7 Variable flow in both distribution and chiller loops ensures chillers receive the warmest possible entering return water temperatures, optimizing chiller and system performance.8

- Building Design and Equipment:

- New Construction: Designing in-building HVAC equipment in new buildings to achieve acceptable ΔTs is feasible and less costly than retrofitting existing buildings.

- Cooling Coils: Selecting cooling coils with a minimum of six rows and 12 to 14 fins per inch (5 to 6 fins per cm) can achieve a ΔT of 12°F to 16°F (6.7°C to 8.9°C) or higher at full load.9 For optimal performance, coils should maintain high fluid velocity in the turbulent flow range even at reduced loads.

- Control Valves: The use of two-way modulating control valves, especially pressure-independent control valves (PICVs), is crucial for achieving high ΔT. Eliminating three-way valves from terminal units is also essential.

- Variable Flow: Implementing variable chilled water flow on both the central plant and customer sides is necessary to optimize ΔT and save pump energy.

- Thermal Storage: Systems utilizing thermal energy storage, particularly ice-based systems, can result in lower chilled water supply temperatures and thus higher ΔT values.10 Chilled water storage systems operating with higher ΔT also see reduced required storage volume.11

Conclusion

Achieving an optimal chilled water delta T (ΔT) in modern district cooling systems is critical for maximizing energy efficiency, reducing operational costs, and minimizing infrastructure requirements. By targeting a design ΔT within the recommended range or even higher in thermal storage applications, engineers can enhance system performance while lowering pumping energy and pipe sizing demands. Key factors such as variable flow design, high-performance cooling coils, two-way control valves, and proper chiller sequencing play a pivotal role in maintaining high ΔT values. For new constructions, integrating these principles early in the design phase ensures cost-effective implementation, whereas retrofitting existing systems may require strategic upgrades. Prioritizing a high ΔT not only aligns with sustainable cooling practices but also supports long-term economic and operational benefits in district cooling networks.

References:

- Ashrae District Cooling Guide ↩︎

- Ashrae District Cooling Guide ↩︎

- IDEA District Cooling Best Practice Guide ↩︎

- EPRI EM-3981 Commercial Cool Storage Design Guide ↩︎

- Ashrae – Design Guide for Cool Thermal Storage ↩︎

- ASHRAE Owners Guide for Buildings Served by District Cooling ↩︎

- Ashrae District Cooling Guide ↩︎

- Ashrae District Cooling Guide ↩︎

- Ashrae District Cooling Guide ↩︎

- Ashrae District Cooling Guide ↩︎

- Ashrae – Design Guide for Cool Thermal Storage ↩︎